Pleasing customers isn’t just about the flow of products to the consumer – it’s also about when products are returned. Returns management software is the only supply chain software that can manage the total, end-to-end returns process for your operations and your customers.

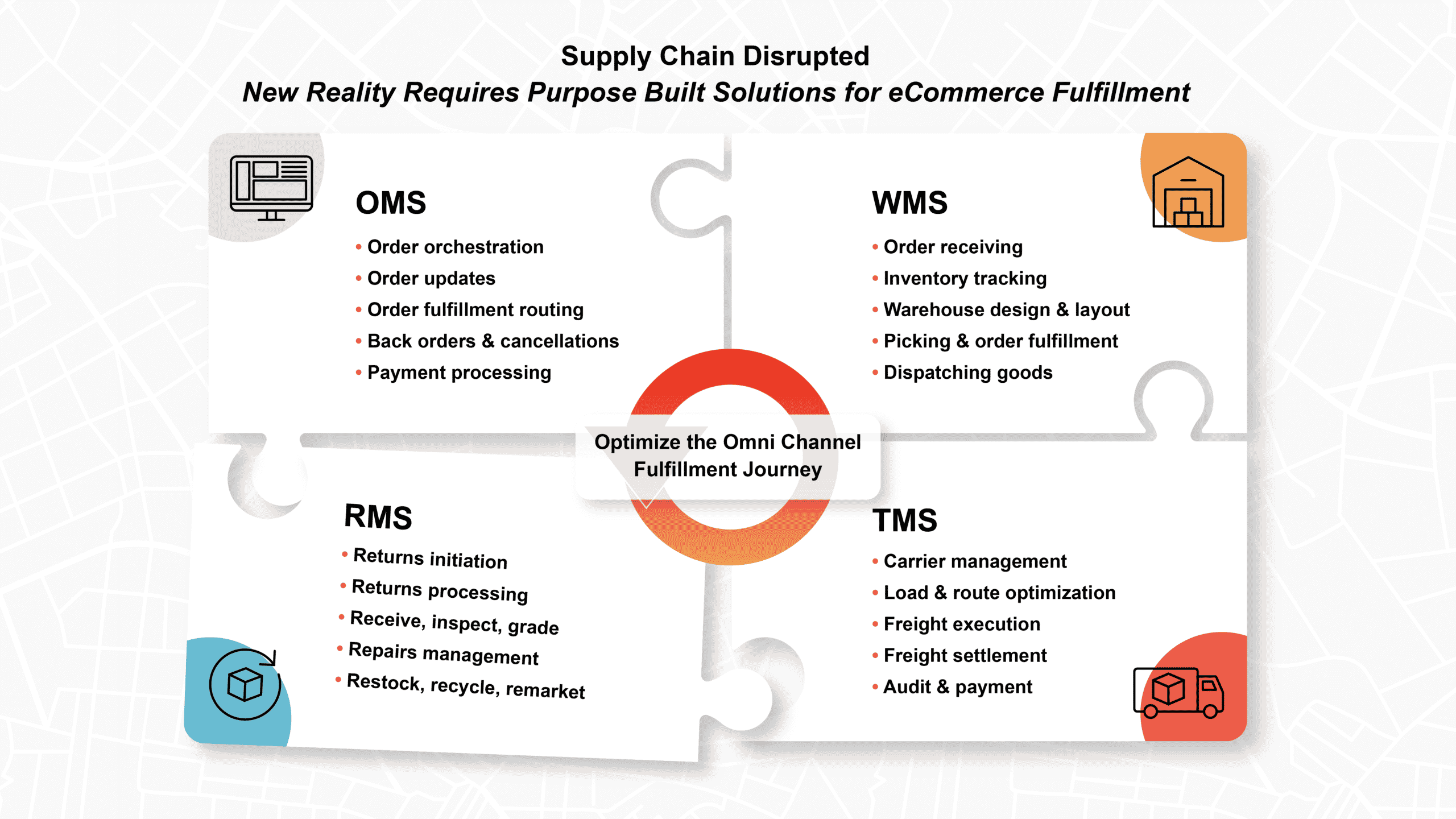

Think of a returns management system (RMS) as the final piece of the supply chain software puzzle. Along with an OMS, WMS and TMS, it optimizes the entire fulfillment journey.

Returns management is a term that covers many facets of a product’s return journey, so it can be overwhelming to figure out which aspects to prioritize. That’s why we’ve put together the “five Rs” that are generally considered to be the foundational components of returns management. Let’s take a look at each one.

Returns

Returns are the first step in reverse logistics flow. No matter the reason for the return, the key to handling it is having the best processes in place for receiving, inspecting and testing the returned product.

In a B2C environment, this includes a branded customer portal, RMA initiation, reason codes, exchanges, shipping labels, check status, and automated customer notifications. B2B returns include these as well, along with validations, approvals, and supporting documentation.

Recalls

Another return format is recalls. They are more complex than a return because they typically involve a product default or a potential hazard. Government regulations and liability concerns may also be involved. If possible, salvaging revenues after recalls can help build brand trust quickly.

Recycling

Sustainable practices are at the forefront of many industries. In industries such as electronic and tech, recycling is on the rise. This might mean using a third-party recycling company in some situations. In other cases, some companies have found success with reclamation efforts for tech devices.

No matter how you address recycling opportunities, think about how you want to handle returns in terms of cost, seasonality, labor capacity and other factors. Rely on RMS data to get a better understanding of your sustainability efforts and how they impact operations.

Repackaging

Returned parts might be remanufactured if no actual trouble is found during testing, and this could also happen if they’re able to be repaired without a large cost. In many cases, the same facility can be used for repackaging returns for resale using secondary channels like overstock.com.

Repair

For areas where faults in products aren’t particularly severe, the issue can be identified and repaired. If a product has indeed reached the end of its life but still has functional parts, these components might be harvested for later use. For repairs involving multiple depot levels, an RMS can handle transferring the repairable units to the proper level so that inventory is processed and restocked with total efficiency and visibility.