Smartly managing product returns means much more than putting the item back on the shelf or on your eCommerce site. To minimize cost and maximize resource efficiency, your process should be able to answer questions like:

- Is it still a good time of year to sell the item, or is it out of season?

- Are there sustainability factors we should consider (such as recycling) instead of throwing it away?

- Are there recommerce factors, such as sending the return to a marketplace site for resale?

- Is the item repairable or is it beyond economic repair? Can in-demand parts be harvested?

- Is the item in demand in another market or geography, where we could get a better price for it?

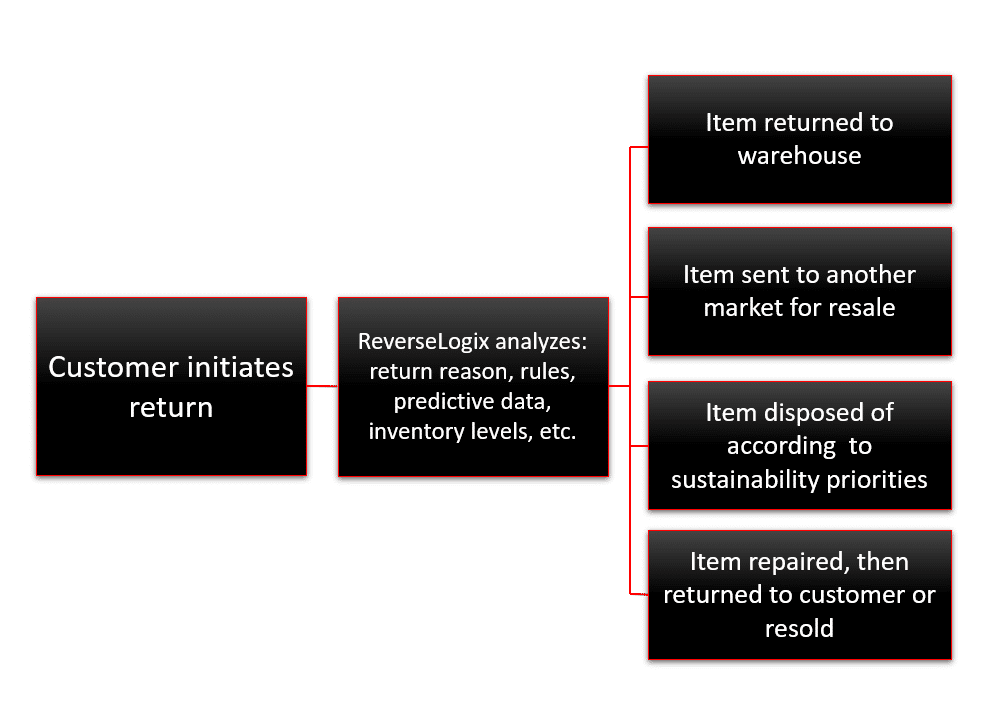

Answering these questions can’t be done efficiently or effectively with manual processes. There are simply too many variables – some of which change depending on the economy, corporate priorities and the time of year. This is where the ReverseLogix returns management system comes in.

The National Retail Federation estimates that only about 50% of returned products are sold. Many are landfilled or burned.

Using ReverseLogix Returns Management System for Auto-Routing Returns

Only the ReverseLogix returns management system (RMS) has the ability to take in complex rules and auto-route product returns accordingly. We do this uniquely well due to our end-to-end returns management capabilities.

According to the Reverse Logistics Technology Survey, respondents said adding automation would make the biggest impacts in receiving, inspection and sorting.

ReverseLogix RMS can be configured according to a multitude of rules, including rules specific to a facility or store location. Retailers, eCommerce sites, manufacturers and 3PLs rely on our extremely flexible RMS to make their product returns faster, more efficient and less costly.

For example, ReverseLogix RMS may auto-route a customer return and bypass the warehouse entirely.

- A sweater returned by a Florida customer in February can be auto-routed to a store in Minnesota where it has a higher likelihood of being resold.

- A ReverseLogix customer has configured the RMS to recommend customers return their product to the nearest retail store (depending on the customer’s proximity to it) instead of mailing it to a warehouse. Managing the return in a store is less costly than a warehouse and gets it back on the shelf more quickly.

Besides seasonality, ReverseLogix RMS can be configured for other parameters, including:

- Geography

- Sustainability goals/factors (recycling, miles driven, truck emissions, etc.)

- Cost/market conditions

- Probability of resale

Decision Framework: How ReverseLogix RMS Auto-Routes Returns

“We sort inventory to go to storage and sort it to go to our pick module. Before ReverseLogix, we sent everything to the pick module, sorted it, and sent it back to the storage location. So we’ve increased our throughput and accuracy because we’re not handling an item as much.”

– Director of Distribution Operations, Global Retailer

Smart auto-routing requires good data

Auto-routing can’t happen without granular returns data. Because ReverseLogix integrates with other supply chain systems, you’ll unlock new visibility into the entire lifecycle of your returns. This includes data for key metrics like process improvements, sustainability considerations and productivity/cost factors.

The ReverseLogix data feeds into demand forecasts and predictive analytics, helping you fast-track returns to get them repaired, resold or disposed of.

“Now with reports about reason coding, how often returns are happening and how many products are in bad shape, we’re getting control of the process. We can help brands decide what needs to be improved and reduce the number of returns in general.”

– Kai Bahlmann, Vice President of Warehousing, Amer Sports