Revolutionizing Retail: The Sustainable Shift in Returns Management

How Reverse Logistics Fosters Sustainability: Reducing the Environmental Impact of Returns

Reverse logistics is a term all too familiar in the retail industry. In a world of hyper-convenience, where a two-day delivery time is a norm for logistics providers, and customer service must be above and beyond, The industry’s supply chain must contend with another consumer expectation: sustainability.

However, the convenience of online shopping combined with the expected liberal return process or policies supporting it have led to an unprecedented volume of product returns, each with a significant environmental footprint. Beyond the immediate financial implications for businesses, there lies a deeper concern about the sustainability of the returns management process.

Retailers cannot do without product returns because consumers will only favor businesses that offer reverse logistics services. However, these consumers also seek brands that align with their environmental values. Therefore, retailers must scrutinize every aspect of their supply chain operations, including reverse logistics processes.

So, how are retailers supposed to improve customer satisfaction and have a solid reverse logistics plan? Fortunately, a single solution can help with both sides of the problem while improving your entire value chain and supply chain management.

The Environmental Impact of Reverse Logistics Management

The advent of online shopping has transformed the supply chain of the retail landscape, offering unparalleled choice and flexibility for shoppers with a single click. However, this convenience has a hidden environmental cost, especially regarding customer returns.

According to the National Retail Federation (NRF), roughly $743 billion of products were returned in 2023. Each returned item signifies a missed match between consumer expectation and product reality and adds to a growing environmental burden.

Each return begins the reverse logistics operations, significantly contributing to carbon emissions. Goods need to be packaged and shipped to their place of origin, being the retailer or manufacturer. The transportation of returned goods often requires multiple modes of transit, from trucks to aircraft, each step adding to the carbon footprint. Roughly 24 million metric tons of CO2 emissions are generated from the e-commerce reverse logistics process alone.

Adding to the environmental impact is packaging. While packaging plays a crucial role in protecting products during transit (forward logistics or product return), it also represents a considerable source of waste, particularly when dealing with customer returns. E-commerce generates 4.8 times more packaging waste than traditional brick-and-mortar stores.

Returned products often require additional packaging for the return journey, leading to increased use of cardboard, plastic, and other materials, most of which will end up in a landfill.

So the question is, what can retailers do about this growing problem?

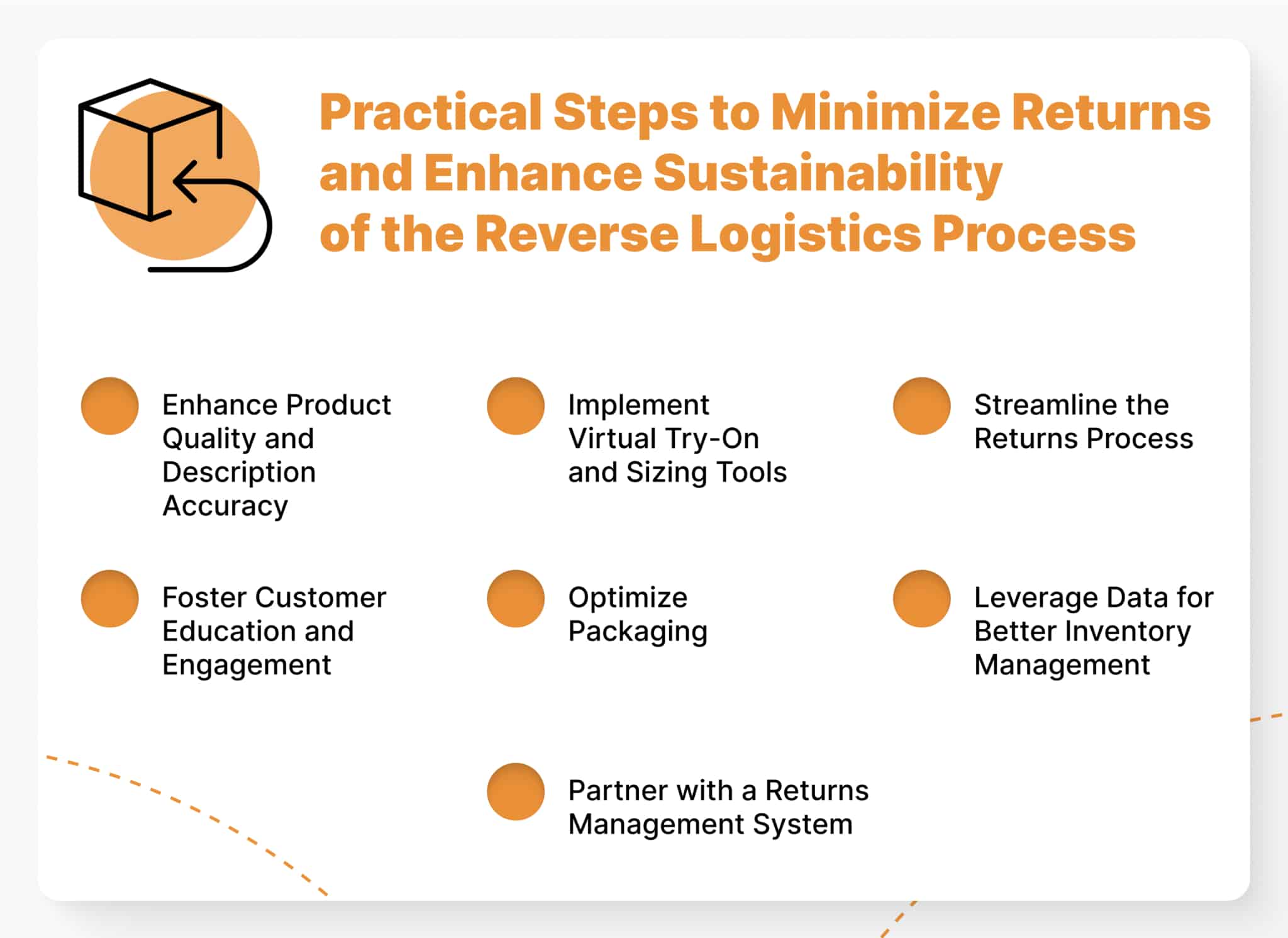

Practical Steps to Minimize Returns and Enhance Sustainability of the Reverse Logistics Process

Obviously, the reverse logistics process is generating a sustainability problem, and it’s a problem that’s still growing. Fortunately, there are some easy steps to improving your reverse logistics services that can help with managing returns a lot better.

Enhance Product Quality and Description Accuracy

Ensuring that products are of high quality and accurately described online can significantly reduce the rate of customer returns. This involves providing detailed product specifications, clear images from multiple angles, and incorporating customer reviews to give a realistic expectation of the product.

Implement Virtual Try-On and Sizing Tools

AR (Augmented Reality) technology advancements allow retailers to implement virtual try-on features for products like clothing and accessories. This can help simplify the entire process for the consumers, reduce the guesswork, and minimize returns due to poor fit.

Streamline the Returns Process

While the goal is to reduce returns, making the process straightforward for consumers is crucial. A clear, easy-to-understand returns policy that is easily accessible can enhance customer satisfaction and loyalty. Additionally, providing multiple return options, such as in-store or via mail, can improve experience and customer retention.

Foster Customer Education and Engagement

Educating customers on the environmental impact of returns, what reverse logistics processes encompass, and why they need to make more considered purchases can decrease return rates. This can be achieved through targeted marketing campaigns, sustainability pledges, and incentives such as store credit for keeping products.

Optimize Packaging

Switching to sustainable business practices, such as better packaging options that are also designed to minimize damage during shipping, can reduce the need for returns. Using recyclable, biodegradable materials supports the environment and resonates with eco-conscious consumers.

Leverage Data for Better Inventory Management

Utilizing data analytics to understand buying patterns, product preferences, and return trends can help retailers stock more effectively, reducing overstock and the need to return unsold goods to suppliers. You can also improve inventory management with analysis techniques like FSN.

Partner with a Returns Management System

Implementing a system like ReverseLogix can transform the returns management process by providing actionable insights into why returns happen and how to prevent them. By optimizing returns management, retailers can significantly reduce their environmental footprint, align with sustainability goals, and ultimately support a more sustainable future.

By adopting these practical steps, retailers can directly address the environmental cost of returns, moving towards a more sustainable and responsible retail ecosystem. These strategies benefit the planet and build a stronger, more positive relationship with consumers who are increasingly seeking out brands that prioritize sustainability.

Leveraging ReverseLogix for a Sustainable Returns Management Process

ReverseLogix is a returns management software that emphasizes the importance of data in making the return process more sustainable. Through detailed analytics, your company gains insights into the lifecycle of returns, identifying opportunities to reduce waste, lower transportation emissions, and decrease material consumption.

Here’s how it works:

Minimizing Returns Through Insight: At the heart of ReverseLogix’s strategy is the reduction of “controllable returns” by addressing their root causes. Whether it’s quality issues, sizing problems, or illegitimate returns, ReverseLogix provides actionable data to tackle these problems directly.

Resale, Repair, and Recycling Prioritization: ReverseLogix enables brands to make informed decisions about handling returns in the most sustainable way possible. Companies can set priorities that balance economic and environmental considerations by analyzing the costs and logistics involved in receiving, handling, and processing returns. This includes determining the best avenues for reselling, repairing, or recycling returned items to minimize their environmental impact.

A Centralized Solution for Sustainable Returns: ReverseLogix’s returns management system offers a comprehensive, end-to-end solution that enhances visibility and control over managing returns processes. By preventing unnecessary returns, facilitating re-commerce, prioritizing repairs and recycling, and minimizing emissions and waste, ReverseLogix positions brands to meet their sustainability goals effectively while improving customer satisfaction.

Ready to step up your reverse logistics game? Click here to get started.